Evaporative cooling is the most energy-efficient and environmentally friendly climate control system used for temperature relief within the food manufacturing sector.

When it comes to cooling modern manufacturing facilities, there are three main methods that can be used, either as a stand-alone solution or combined together as a so-called hybrid solution. These are mechanical ventilation, refrigeration-based air conditioning and evaporative cooling.

Neglecting building indoor air quality while pursuing other energy efficiency goals, such as tighter building envelops, can result in building environments that negatively impact the health, comfort and productivity of your employees - defeating the overall goal of building design, which also includes reduced costs. Over the years evaporative cooling has become the most desirable out of the three cooling methods mentioned above, due to its ability to meet the demands of facility cooling without the associated high capital and running costs.

Unlike air conditioning systems that use re-circulated air, evaporative cooling systems circulate cool fresh air through a building and force out the stale hot air. The fresh air from the outside is cooled by passing it over water and is then directed around the building by a fan.

Cooling through evaporation is not without precedent in nature; the perfect and most simple example being human perspiration. As perspiration evaporates it absorbs heat, while cooling our bodies at the same time. The same principle applies to evaporative cooling of machinery and buildings.

What are the different types of evaporative cooling?

There are two types of evaporative cooling - direct and indirect. The two methods operate in very different manners and most concerns related to evaporative cooling, such as introducing humidity into the environment, are actually related to direct evaporative cooling.

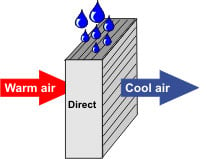

Direct evaporative cooling

Direct evaporative cooling is the simplest form of evaporative air conditioning, which is widely applied in dry regions. This system tends to use a fan to draw hot air from the outside environment that is then passed through a wetted medium. The water absorbs heat from the air as it evaporates from the wetted medium and the air leaves the evaporative cooler with a lower temperature. The water that remains is also cooled as a byproduct of the evaporative process.

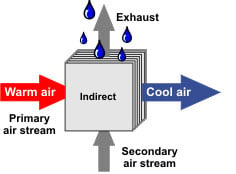

Indirect evaporative cooling

Indirect evaporative cooling on the other hand takes the water that was cooled as described in the direct evaporative cooling process and pumps it through a water coil. When the supply air is passed through the coil it cools sensibly (no added moisture). Hence, indirect evaporative cooling supply air has no contact with water.

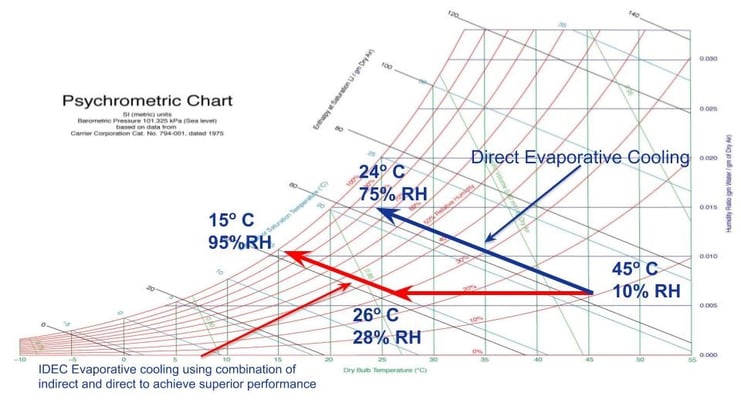

The efficiency of evaporative cooling tends is measured by comparing the dry bulb and wet bulb temperatures to give the wet bulb depression. Below is a psychrometric chart showing how the combination of direct and indirect evaporative cooling can offer 125% wet bulb cooling efficiency whilst introducing up to 50% less moisture into your environment.

Why is evaporative cooling well suited to food manufacturing environments?

With proven low capital costs and long-term low running costs, evaporative coolers can be used in any environment and industry sector, regardless of the scale of your facilities, or whether any shutter doors or windows are open.

Research and Markets’ statistics, featured in the Global Evaporative Cooling Market - Growth, Trends and Forecasts (2016-2021) report, show that the global evaporative cooling market is projected to grow from $4.48 billion (£3.37 billion) in 2015 to $5.95 billion (£4.39 biliion) by 2020, with a 5.84% Compound Annual Growth Rate. The reason for this being, that more and more companies are realising the cost saving and environmental benefits and adopting the process.

However, while evaporative cooling can be used in virtually any industry sector, it certainly offers most benefits to food manufacturers due to the fact that the high temperature within the facilities significantly reduces the level of humidity - making most of the concerns related to evaporative cooling irrelevant and creating the environment needed to increase the method’s operational efficiency.

From our experience we know that a lot of food manufacturing companies are still using general ventilation equipment and open doors to reduce overall heat. However, this often proves to be ineffective, resulting in a stuffy environment with little or no air movement, especially during those warmer summer months, accompanied by very high energy consumption costs.

According to the Chartered Institute of Building Services Engineers, the recommended temperature for heavy work in factories is 13℃ and light work in factories is 16℃. Not only can heat cause poor working conditions for your employees and affect their productivity and health, but it can also result in damaged products and stock, as well as become a health and safety issue and increase the risk of accidents due to tiredness and dizziness. With a combined effort of cooling and strategically placed ventilation, evaporative cooling can solve these problems with unprecedented energy efficiency and incredible cost reduction.

Evaporative cooling can offer:

- Improved efficiency and operational capability by introducing fresh, cool air in your facility

- Elimination of the use of refrigerant gases

- Reduction of carbon emissions; as well as

- Improve your corporate environmental credentials.

The cooling system boasts not only key environmental benefits, but delivers incredibly high efficiency rates due to its remarkably low energy consumption rates. Evaporative coolers are far more economical than any other conventional air conditioning system and can produce 35kw of air cooling for every 1.5kw of electricity consumed.

A project that we’re currently working on with Tesco, is set to upgrade the company’s in-store cooling systems by implementing our innovative Air₂O IDEC evaporative cooling air conditioning technology - expected to lower the energy usage of Tesco’s environmental systems by 80%.

Evaporative cooling can achieve an average decrease of up to 90% of your air conditioning costs. It’s easy to make grand statements as such, but how plausible is this, actually? Why not find out for yourself with our quick and easy Evaporative Cooling Calculator and find out how much you can save based on your specific circumstances.

Comment on my blog