Evaporative cooling uses evaporation to cool the air. The evaporative cooler, also known as swamp cooler, consists of three main components - a pump, cooling pad and a fan.

The way the process works is quite simple. Within the evaporative cooler there is a pump which circulates water from the reservoir onto a cooling pad. The pad in turn becomes wet. Within the cooler there is also a fan, which draws air from the outside environment, going through the moistened pad. As the air passes through the pad, the air is cooled by evaporation.

When we’re looking at evaporative cooling systems, there are two temperatures that you need to be aware of. These are:

The dry bulb temperature - the natural temperature of the air surrounding us, which we tend to measure via a thermometer.

The wet bulb temperature - the lowest temperature that can be reached through the evaporation of water only.

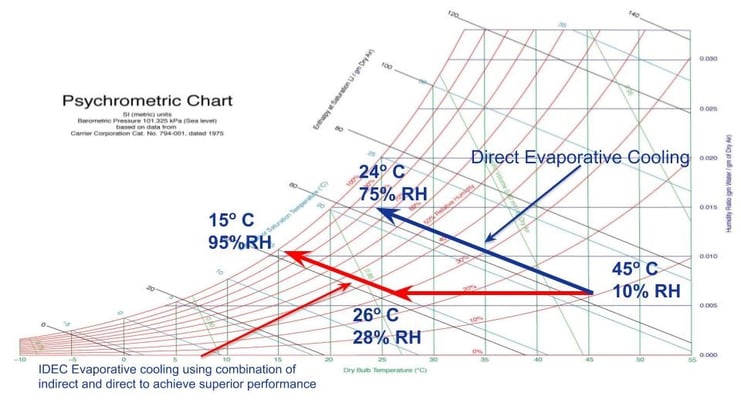

Below is a psychrometric chart of the direct and indirect evaporative cooling processes. To find out more about what is evaporative cooling, click here to read our blog.

Energy is required to change water from liquid to vapour and this energy tends to be obtained from the air itself. The air entering the cooler gives up heat energy to evaporate the water. During this process, the dry bulb temperature of the air passing through the cooler is lowered and distributed back into the environment. An important point to understand is that the temperature of water doesn’t have any impact on the cooling produced by the evaporation process.

A very important factor for evaporative cooling to work effectively is humidity of the air. Evaporation only takes place when the humidity of the air is below 100%. The lower the humidity, the more effective the evaporative cooling process would be. The way the potential of evaporative cooling is measured is by assessing the wet bulb temperature, as compared to the air’s dry bulb temperature. These two indicators are used to calculate the relative humidity.

While statistics show that the air humidity in the UK tends to range between 88-92% depending on which part of the country you’re located in, still it tends to be relatively low when the temperature is high. This creates the perfect environment for evaporative cooling, especially within the food manufacturing and bakery sectors, where the facility’s temperature tends to be very high, therefore, a drop of over 10℃ - 12℃ during peak temperatures can be achieved.

What about evaporative coolers?

One of the major differences between an evaporative cooler and a portable or a fitted system is that the evaporative cooler doesn’t have exhaust hoses or outside condenser boxes. They are also different from air conditioners in that they don’t provide ‘refrigerant air’, but ‘cooled air’.

What makes evaporative cooling so appealing is its incredible cost-efficiency, with the ability to reduce your running costs by up to 90%, as well as the fact that it’s the most environmentally friendly solution out of all options available on the market due to the fact that it introduces fresh air, free of refrigerant gasses.

How to ensure you’re maximising your evaporative cooling results?

The key to effective evaporative cooling is ensuring that each of the cooling pads are completely saturated at all times during operation and that the system’s fan and motors are sized and designed to deliver the appropriate airflow for your facility.

Working with an experienced supplier that possesses knowledge of the specific demands of your industry sector, such as reduction of downtime and ensuring that installation and commissioning of the system are executed without any contamination risks, is absolutely critical.

However, we also shouldn’t forget the fact that evaporative cooling is not always the right solution for your needs and might even be the wrong one depending on your sector, environment or location where you’d like it installed. Some restrictions to the appropriate use of evaporative coolers include things such as:

- They must not be used in closed or unventilated areas, as they rely on the flow of fresh air to enable the process to work

- Having been filled with water, if they’re used in an unventilated air they would only end up pumping humidity in the area, making it damp and resulting in mould and other subsequent damage to electrical systems or contents in that area.

Here at Cosaf, we are experts in providing cost-effective cooling solutions and are the pioneers in the food manufacturing sector. Our expertise and experience allow us to provide our clients with the the most efficient solution for their needs, whether this is evaporative cooling as a standalone solution or combined with traditional cooling systems packaged in a hybrid cost-effective solution.

We have put together this quick and easy to use Evaporative Cooling Calculator that provides you with an indicative quote on exactly how much evaporative cooling could save you. Click on the link below to find out now.

Comment on my blog